The Evolution of Prismatic Aluminum Shell Battery Cell Dimensions (2010-2026)

For approximately 15 years, the domestic market for prismatic aluminum shell power and energy storage cells has undergone rapid development. During this period, technologies in cell materials and manufacturing have achieved leapfrog innovations, driving multiple rounds of iteration in cell size specifications.

This article outlines the historical trajectory of these dimensions, from the early chaotic phase to the standardized VDA era, and finally to today's highly integrated CTP (Cell to Pack) and Blade battery technologies.

1. The Pre-VDA Era (Approx. up to 2014)

This phase marked the industry's infancy, primarily focused on pure electric buses and limited energy storage demonstration projects. During this time, there were no unified standards for cell dimensions.

Key Legacy Specifications

Several cell specifications became industry classics during this period. Notably, the 36*130*207mm dimension from Chunlan was widely adopted by companies like Narada, EVE Energy, and Vision. EVE Energy's application of this size for the LF80 cell in commercial vehicle standard boxes became a representative product of this era.

| Manufacturer | Capacity (Ah) | Thickness (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|

| CATL | 80 | 29 | 135 | 220 |

| CALB | 72 | 29 | 135 | 220 |

| Chunlan | 60 | 36 | 130 | 207 |

| Lishen | 20 | 27 | 70 | 134 |

| Gotion | 12.5 | 18 | 65 | 140 |

2. The Passenger Car VDA Era (2014-2019)

The term "VDA" refers to the German Association of the Automotive Industry. Their standard, DIN SPEC 91252:2011-01, established specific dimensions for prismatic cells that heavily influenced the Chinese market.

Among the VDA standards, the PHEV2 and BEV2 specifications (and their derivatives) became the most widely used platforms over the past decade. Modules designed around the PHEV2 size are famously known as "VDA Modules".

The Dominance of PHEV2

The PHEV2 specification has supported the entire development process of China's new energy passenger vehicles. These cells are categorized by thickness multiples: 1x, 1.5x, 2x, and 3x thickness.

- Standard Thickness (1x): CATL's 37Ah NCM cell (26.5*148*91mm) is a prime example. It was used in the BMW 5 Series PHEV and was the first mass-produced NCM cell for passenger cars in China.

- Multi-Thickness Variants: Thicker versions allowed for higher capacities, such as the CATL 177Ah (79*148*103mm) or the CALB 114Ah (52*148*117mm).

3. The Era of MEB Platform and CTP Technology (2020 - Present)

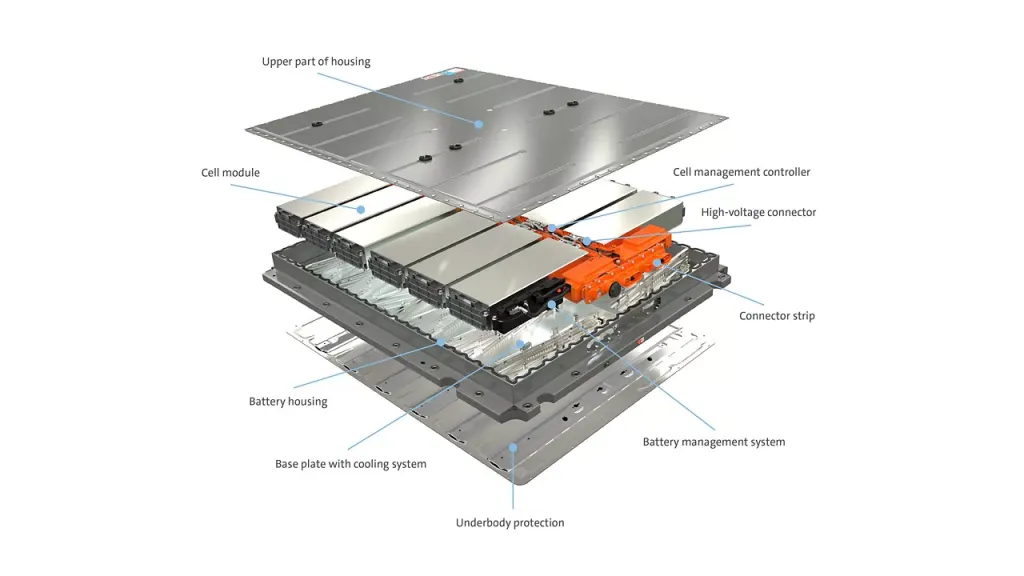

In October 2015, Volkswagen announced the MEB (Modular Electric Drive Matrix) platform. The standard battery module size for MEB is 590*225*(107-112)mm, commonly referred to as the "590 Module".

MEB-Standard Cells

To fit the 590 module, prismatic cells were designed with a standard width of roughly 220mm. Dimensions such as 33*220*103mm (CALB) and 44*220*113mm (Ruipu) became mainstream solutions for passenger vehicles.

CATL CTP and "MEB-Like" Cells

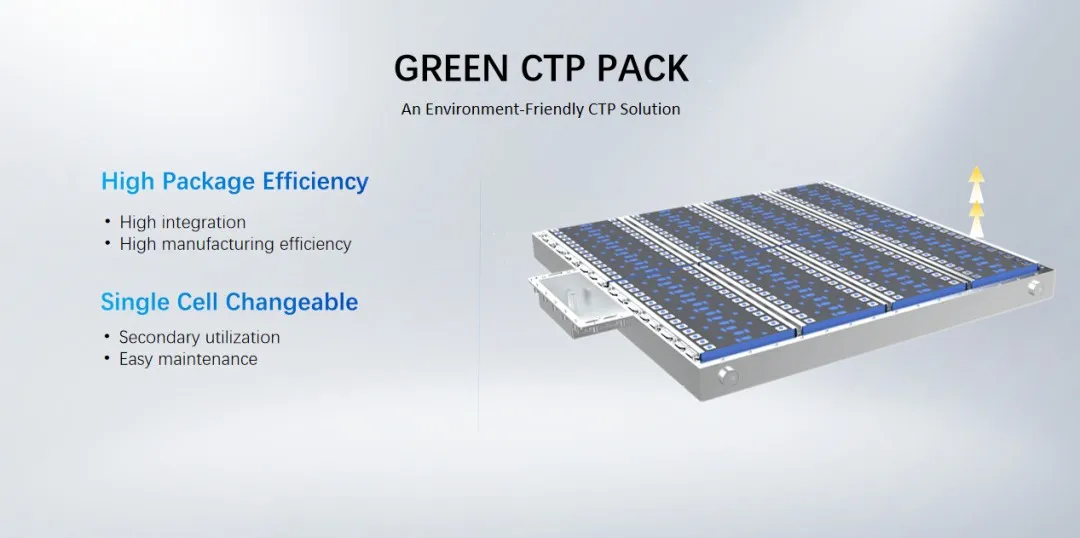

In 2019, CATL introduced CTP (Cell to Pack) technology, eliminating modules to improve space utilization. This led to "MEB-like" products where the overall shape resembles MEB cells but dimensions vary slightly to optimize the pack.

| Manufacturer | Capacity (Ah) | Chemistry | Dimensions (T*W*H mm) |

|---|---|---|---|

| CATL | 163 | NCM | 50.7 * 194 * 115 |

| EVE | 166 | NCM | 50.7 * 194 * 113 |

| EVE | 178 | LFP | 31 * 280 * 88.6 |

| CATL | 161 | LFP | 62 * 280 * 82 |

4. The Rise of "Blade" Batteries

While BYD had long utilized horizontal cells, the 2020 launch of the "Blade Battery" marked a turning point. BYD lengthened and thinned their horizontal cell design, combining it with "skip-module" technology to achieve high safety (passing the nail penetration test) and high volumetric density.

Following this success, other manufacturers introduced similar "Short Blade" (SVOLT) and "Aegis" (Geely) battery products. Today, Multi-VDA, MEB/CTP, and Blade batteries constitute the three mainstream solutions for passenger vehicles.

5. Commercial Vehicle Battery Evolution

Around 2016, CATL introduced standardized boxes for buses, which rapidly became the commercial vehicle solution. These cells evolved from the VDA BEV2 specification (45*173*115mm).

The "Standard Box" Core Cells

Through continuous iteration, two specific sizes have become the core products for bus and heavy truck standard battery boxes:

- 54 * 173 * 207 mm (e.g., CATL 223Ah, Penghui 150Ah)

- 71 * 173 * 207 mm (e.g., CATL 302Ah)

6. The Energy Storage (ESS) Standard: 280Ah and Beyond

In 2019, CATL launched the 280Ah energy storage cell. This product was derived from the commercial vehicle 71*173*207mm chassis but optimized for long cycle life.

The 280Ah (and its successor, the 314Ah) became the definitive standard for large-scale energy storage. The industry is currently transitioning from the traditional 280/314Ah specifications toward "314Ah+" capacities.

7. Next-Generation Energy Storage Cells (2025)

In 2025, various battery cell manufacturers have successively released their next-generation energy storage cell products. Their capacities have significantly improved compared to the previous generation of 280Ah and 314Ah cells, and the cell dimensions and integration methods are also diverse.

We have summarized the next-generation energy storage products from several top battery cell manufacturers by shipment volume in 2025, including CATL, BYD, CALB, EVE Energy, etc., to share with our readers.

Table 3: 2025 Next-Generation Energy Storage Cell Specifications

| Cell Manufacturer | Capacity (Ah) | Arrangement Type* | Process Route | Dimensions (mm) |

| CATL | 587 | Vertical | Winding | 73*275*218 |

| BYD | 2170 | Horizontal | Lamination | No data available |

| CALB | 392 | Vertical | Winding | 75*182*225 |

| CALB | 588 | Vertical | Winding | 72.5*288*216 |

| CALB | 684 | Side-mounted | Lamination | 54*500*173 |

| EVE | 628 | Vertical | Lamination | 72*352*207 |

| HTHIUM | 587 | Vertical | Winding | 73.5*286*216 |

| HTHIUM | 1175 | Vertical | Lamination | 75*580*216 |

| REPT | 392 | Vertical | Winding | 75*182*225 |

| REPT | 588 | Vertical | Winding | 72.5*288*216 |

| CORNEX | 472 | Vertical | Winding | 73.7*220*225 |

8. Niche and Specialized Dimensions

- VDA-HEV (12.5*120*85mm): Rarely used due to the limited market for non-plugin hybrids in China. Primarily used by Sunwoda for Nissan E-Power.

- Logistics "T-Box" (33200 Series): Developed around 2018 by CATL for logistics vans. Typical sizes include 33.2*200.7*172mm (125Ah) and 33.2*200.7*207mm (150Ah).

- 50160 Cell: Developed around 2020 by Huawei and partners for telecom power (48V100Ah). The 50*160*118mm size is now synonymous with 100Ah small storage systems.

- Volkswagen Unified Cell (UC): A collaboration between VW and Gotion. It resembles a hybrid of "MEB-like" dimensions and "Blade" packaging logic.

Future Outlook

Passenger Vehicles: The market will likely remain dominated by "MEB-like + CTP" solutions alongside Long/Short "Blade" form factors.

Commercial Vehicles: Following CATL's 2024 "Tianxing" release, standard box forms are changing. While no single new cell spec has emerged yet, manufacturers are expected to leverage their existing storage or passenger car lines to offer diverse solutions, including vertical, side-mounted, and blade-style configurations.