Tesla’s 4680 Battery "Complete Form": Unlocking the Mass Production of Full Dry Electrode Technology

The automotive world has waited years for the fulfillment of the promise made during Tesla’s 2020 Battery Day. That promise was the 4680 large cylindrical cell—a battery measuring 46mm in diameter and 80mm in height—designed to be the absolute core of Tesla’s vision for "cost reduction and efficiency enhancement."

According to Tesla’s calculations, the 46mm diameter represents the optimal solution for balancing range and manufacturing capability, delivering substantial cost reductions. When compared to the previous generation 2170 cells, the 4680 battery offers five times the energy capacity, boosts vehicle range by 16%, and delivers six times the power output.

However, the 4680 is not a single piece of technology. It is a complex system engineering feat that integrates tabless design, dry electrodes, steel casings, and unified die-casting. While the journey began with concept releases and navigated through difficult process bottlenecks, the ecosystem has finally matured. By the fourth quarter of 2025, Tesla’s Giga Texas factory in Austin achieved a monumental breakthrough: the mass production of fully dry electrodes for both the cathode and anode. This milestone marks the evolution of the 4680 cell into its "complete form."

Initially, the technical hurdles of the dry electrode process forced Tesla into a compromise. Early versions utilized a "hybrid" approach: a dry process for the anode but a traditional wet process for the cathode. This was because cathode materials are far more complex, making uniform dry coating notoriously difficult. Achieving a full dry process for both poles means Tesla has finally severed the shackles of wet manufacturing. This breakthrough doubles the efficiency benefits and signals the ultimate maturity of their manufacturing system.

This article analyzes the evolution of the 4680 cell, dissecting the engineering behind the dry electrode revolution and why it renders traditional battery manufacturing obsolete.

Inside the Innovation: The Four Pillars of the 4680 Ecosystem

To understand why the "complete form" 4680 is revolutionary, we must look at the four specific technologies that power it.

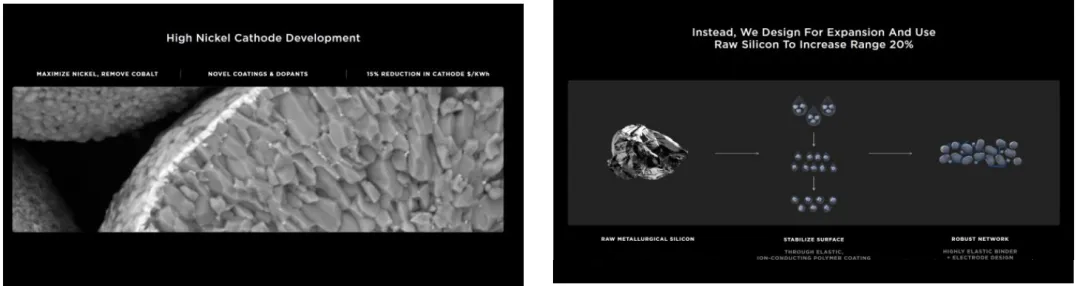

1. High-Nickel Cathodes and Silicon Anodes

Tesla significantly boosted energy density by altering the chemical composition of the battery.

- High-Nickel Cathode: Increasing nickel content directly improves energy density. Furthermore, by reducing the reliance on cobalt—a notoriously expensive and ethically complex material—Tesla lowers the cost of the cathode significantly.

- Silicon Anode: Silicon holds a theoretical specific capacity far higher than the existing graphite systems. By integrating a high-capacity silicon-based anode, the battery stores more energy in the same footprint.

2. Tabless (All-Tab) Technology

This innovation addresses the physical constraints of larger batteries. Traditional 2170 cells use a single tab, forcing electrons to travel the entire length of the wound foil, which generates heat and resistance.

The 4680 employs a "Tabless" design. Here, the entire edge of the foil acts as a connection. Electrons only travel the short axial distance (height of the battery) rather than the long winding length. This shortens the electrical path, increases the conduction area, and drastically lowers internal resistance. Consequently, the battery runs cooler, enabling ultra-fast charging and high-current discharging without overheating.

3. CTC (Cell-to-Chassis) Integration

Tesla moved beyond the battery pack. CTC implies that the 4680 cells are integrated directly into the vehicle's chassis. The battery becomes a structural component, providing rigidity and strength to the car's body. This eliminates the need for module-level and pack-level structural parts, reducing vehicle weight, lowering costs, and improving system integration density.

4. Dry Electrode Coating (The Core Breakthrough)

This is the manufacturing holy grail. In 2019, Tesla acquired Maxwell Technologies specifically for this IP.

- The Old Way (Wet Process): Manufacturers mix electrode powder with toxic solvents (like NMP) to create a slurry. They coat this slurry onto foil, then run it through massive ovens to dry it out and recover the solvent.

- The Tesla Way (Dry Process): This process mixes electrode powder directly with a PTFE binder. A roller press then crushes this mix onto the current collector. It eliminates the slurry, the solvents, and the massive drying ovens entirely.

Dry Electrode vs. Wet Coating: Solving the Industry’s Oldest Pain Points

The traditional wet process has dominated the lithium-ion industry for decades, but it suffers from severe inefficiencies that prevent further cost reductions. The wet process commits what engineers call the "Four Sins" of manufacturing:

- High Energy Consumption: The drying phase, required to evaporate solvents, consumes 30% to 50% of a battery factory's total energy.

- Pollution and Risk: The process relies on NMP (N-Methyl-2-pyrrolidone), a toxic solvent. Recovering and treating NMP requires expensive equipment and poses environmental and occupational health risks.

- Material Damage: The high-speed mixing and high-temperature drying required by wet processing can fracture the microscopic structures of advanced materials like high-nickel cathodes, degrading battery life.

- Sacrificed Energy Density: To make the wet slurry flow correctly, manufacturers must add significant amounts of non-active binders and additives. These take up space that could be used for active energy-storing materials.

The Dry Process Solution: By removing the solvent, Tesla eliminates the need for slurry mixing, drying ovens, and solvent recovery systems. This saves materials, time, factory floor space, and labor. Crucially, the dry process allows for a thicker electrode coating, which directly translates to higher energy density—perfect for the large format 4680 cell.

Deconstructing Tesla’s Dry Coating Process: The Manufacturing Holy Grail

Why is the dry electrode process often called a "Holy Grail"? Because it requires solving a paradox: fusing materials together physically without a liquid agent. It involves mixing powders (the "ingredients"), calendering them (the "heat"), and using PTFE (the "glue") to hold it all together. A deviation in any step ruins the electrode film.

Here is how Tesla’s "complete form" technology optimizes this process:

1. Performance Superiority

- Enhanced Power: Under identical conditions, dry-coated electrodes offer higher output power than wet-coated ones.

- Higher Density: The dry process creates a higher compacted density. The electrodes can be made thicker without cracking, increasing capacity without sacrificing physical integrity.

- Improved Cycle Life: The process is less destructive to the chemistry, offering better stability at high temperatures and longer cycle life.

- Safety with High Nickel: The chemical inertness of the PTFE binder stabilizes high-nickel cathodes, improving safety without solvents.

- Silicon Compatibility: PTFE is elastic. This elasticity helps accommodate the physical expansion of silicon anodes during charging, solving a major issue with silicon-based batteries.

2. The Manufacturing Blueprint (Patent Analysis)

Tesla’s patent reveals a sophisticated, solvent-free fabrication method designed to protect active materials.

- The Structure: The electrode film consists of active material particles (90-99%) and a very small amount of fibrillizable binder (PTFE), often less than 3% by weight. This is a massive improvement over wet processes that use 5-10% binder, reclaiming valuable space for energy storage.

- The Process:

- Non-Destructive Mixing: Tesla uses low-shear mixing (bladed mixers or acoustic resonance) to blend the cathode powder with the PTFE. This ensures the fragile single-crystal cathode particles are not crushed.

- Fibrillation: The mixing process turns the PTFE into microscopic automated nets (fibrils) that trap the active materials.

- Calendering: The mixture is fed into a rolling press. In fewer than three passes, the machine presses the powder into a self-supporting film.

- Lamination: This film is then laminated onto the foil current collector.

The Verdict: A New Industrial Paradigm

The data supports the hype. Tesla’s testing indicates that batteries produced with this specific dry electrode process maintain nearly 90% capacity after 2,000 cycles (under 100% depth of discharge conditions). This far exceeds the lifespan of traditional wet-process cells.

The history of the 4680 cell is essentially the history of conquering the dry electrode bottleneck. The tabless design solved electron flow; the structural pack solved physical integration; but the dry electrode solved the fundamental logic of manufacturing.

Moving from a "hybrid" process to the "full dry" complete form in late 2025 represents more than just a better battery. It represents a manufacturing paradigm that competitors will find difficult to replicate. By eliminating the most expensive, energy-intensive, and toxic parts of battery making, Tesla has not only lowered the cost floor for electric vehicles but has also created a greener, more efficient path forward for the entire energy industry.