|

Welcome To Evlithium Best Store For Lithium Iron Phosphate (LiFePO4) Battery |

|

There are three primary forms of lithium-ion battery packaging: cylindrical, square, and soft pouch. Each packaging structure has distinct characteristics, with its own set of advantages and drawbacks. In recent years, the soft pouch battery's market share has been progressively increasing. Experts anticipate that the soft pouch battery market share will surpass 50% in the future.

The cylindrical lithium-ion battery boasts mature production technology with high yields. Models like 14650, 17490, 18650, 21700, and 26500 are among the many cylindrical battery types available. This type's production process is mature, resulting in lower PACK costs, higher battery product yield, and consistent PACK quality. Due to the battery pack's large heat dissipation area, it offers better heat dissipation performance compared to square batteries. The cylindrical battery format facilitates various combinations and suits the comprehensive layout of electric vehicle space designs. However, these batteries are usually crafted from steel or aluminum, making them heavier with relatively lower specific energy. Well-established production companies in China, Japan, South Korea, and the United States, such as SANYO, SONY, LG, and Wanxiang A123, specialize in cylindrical batteries.

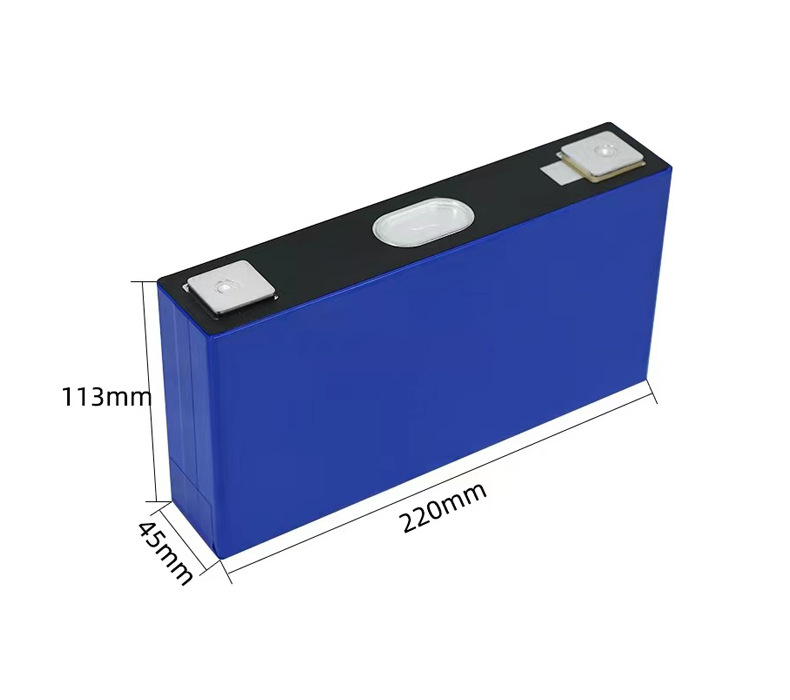

Prismatic battery cells typically use aluminum alloy or stainless steel shells, adopting an internal winding or overlapping process. They provide better protection and significantly improve safety compared to aluminum-plastic film (soft pouch batteries). Aluminum shells have become the mainstream choice due to their lightweight nature, safety attributes, and resulting performance benefits. Companies like kukheon Tech, Samsung SDI, Risen, and Youngdeok Times are notable manufacturers of prismatic batteries. However, due to the vast variety of models available, unifying the manufacturing process for prismatic batteries presents challenges. While square batteries work well for regular electronic products, standard cylindrical lithium-ion batteries are preferred for industrial equipment, ensuring a streamlined production process and easier battery replacements in the future.

Soft pouch lithium-ion batteries utilize flexible packaging materials, predominantly aluminum-plastic composite film, which distinguishes them from traditional steel or aluminum-shell batteries. These batteries feature three layers: an outer resistance layer (typically nylon BOPA or PET), a middle layer of aluminum foil, and an inner functional high-barrier layer. The flexible packaging offers several advantages, including enhanced safety performance, reduced weight (40% lighter than steel shell batteries and 20% lighter than aluminum shell batteries of similar capacity), lower internal resistance resulting in decreased power consumption, longer cycle life, and the ability to be custom-shaped to meet specific design needs. However, their drawbacks include poor consistency, higher cost, and potential leakage. Nevertheless, these issues can be addressed through large-scale production and improvements in aluminum-plastic film quality. Companies like fluorine, China Aviation Lithium, Wanxiang, CITIC Guoan, and Micro-Macro Power are notable soft pouch battery producers.

In the realm of digital consumer electronics, the trend is towards smaller, lightweight batteries. Soft pouch polymer lithium-ion batteries, due to their excellent performance, are widely used in smartphones, tablets, and wearable devices, surpassing the industry average rise rate.

The rise of pouch power lithium-ion batteries in new energy passenger cars has been evident. For instance, BaiC, Changan, Dongfeng, and other high-end domestic electric vehicles have adopted pouch power lithium-ion batteries. Statistics indicate that the output of flexible batteries in China has surpassed that of square and cylindrical batteries, with a continual rise projected.

In conclusion, cylindrical, square, and flexible package batteries each hold their own advantages and disadvantages. Each excels in its specific applications. With the industry's emphasis on battery system energy density, the subsidy policies for new cars are favoring lighter weight and higher range batteries. This shift is expected to benefit flexible batteries, with their higher capacity and lighter weight, making them more prevalent in the new energy vehicle market, potentially surpassing 50% market share in the future.

Edit by editor

Last Update:2023-12-28 19:30:20

All Rights reserved © 2026 Evlithium Limited